Understanding Rapid Tooling Service

Rapid tooling service plays a crucial role in the manufacturing industry by enabling the quick production of prototypes and tools. This method significantly reduces the time and cost associated with traditional tooling processes. Manufacturers can create prototypes that are both functional and accurate, allowing for thorough testing before mass production. The speed of rapid tooling means that any changes in design can be quickly implemented, ultimately enhancing innovation and efficiency. Companies need to embrace this service to remain competitive and responsive to market demands. For more information on how this service works, check out our rapid tooling service.

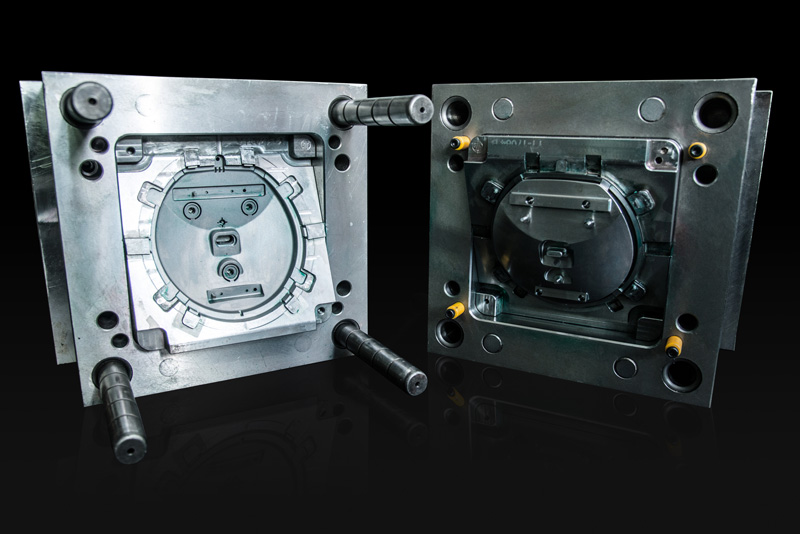

Real-World Applications of Rapid Tooling

Consider a scenario where a consumer electronics company needs to launch a new phone. Using rapid tooling, they can produce molds for their prototypes in a matter of weeks, rather than months. This swift turnaround allows the company to gather user feedback and make necessary adjustments before the final product release. By leveraging rapid tooling services, businesses across various sectors, including automotive and healthcare, can enhance their product development cycles. This iterative process not only saves time but also optimizes resources, translating to cost savings. Effective application of rapid tooling can lead to better product quality and innovation in design.

The Advantages of Custom Rapid Production Tooling

Custom rapid production tooling expands the benefits of traditional rapid tooling by allowing for tailored solutions that meet specific manufacturing needs. By creating unique tooling designs based on individual project specifications, manufacturers can achieve superior precision and functionality in their products. The adaptability of custom rapid production tooling ensures that businesses can scale their operations effectively, accommodating fluctuations in demand without compromising on quality or timelines. This personalized approach enhances the ability to meet customer expectations while also maximizing production efficiency. As firms seek to differentiate themselves, custom tooling becomes a vital asset in fostering innovation.

Making the Most of Custom Rapid Production Tooling

Utilizing custom rapid production tooling often results in greater cost efficiency over time. Companies that invest in this area can typically lower their overall production costs by producing fewer rejects and minimizing waste. Furthermore, achieving a higher level of precision helps maintain quality standards, which is essential for brand reputation. For example, manufacturers in the automotive industry can use custom rapid production tooling to accurately replicate intricate automotive designs, thereby ensuring compatibility and function. The integration of advanced technologies such as 3D printing enhances these tooling capabilities, further streamlining the production process and facilitating faster go-to-market strategies.

Conclusion: Why Choose APT-Mold for Your Manufacturing Needs

In summary, rapid tooling and specifically custom rapid production tooling offer immense advantages for businesses pursuing innovation in manufacturing. By adopting these modern approaches, companies can enhance their production capabilities, reduce costs, and improve overall product quality. APT-Mold stands out in this landscape as a manufacturer with significant supply advantages, offering tailored solutions that cater to your unique tooling needs. For reliable service and quality products, consider choosing APT-Mold as your trusted partner in the manufacturing journey.